Onsite Services

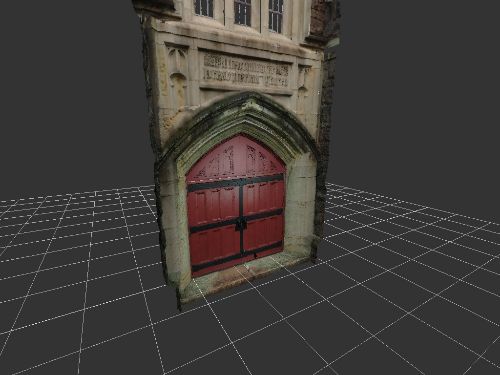

Almost every job requires a shop drawing or two, but it is the project that starts and ends at the jobsite where we really shine. We begin by obtaining field dimensions, templates and mold impressions when original elements still exist. Our tool kit spans from a tape measure and plumb bob to the use of laser scanning of entire facades as the situation requires. Having spent our time on the jobsite, we understand the complexities of construction and the importance of on-time, on-budget delivery and installation.

We work with our clients to ensure our packaging, delivery, and stocking methods best support the needs of each job - whether they are working with a hand cranked hoist or a crane. We supply installation drawings, framing and connection systems, integrated sub-assemblies and, when required, complete shop mock ups and trial assemblies to ensure trouble-free installation. Especially on those projects where we've done mock ups of the structure and cladding, our ability to provide on-site assistance for the layout and erection sequencing can greatly expedite the installation process.

Design and Engineering

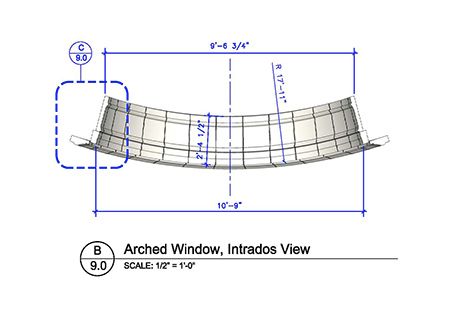

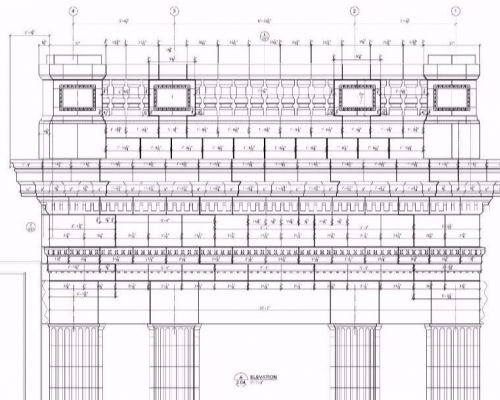

Much of our work involves delegated-design formats, where we’re responsible for the engineering of parts and connection systems, but we’re also engaged on many projects with fully developed construction documents. In a business where the costs of access and field labor can often exceed the part costs, coming up with functional installation approaches can make or break a budget. We focus on designing effective and workable connections tailored to the skills and resources available, and our years of creative problem solving have resulted in a catalog of connection options and methods. If needed, our designer can create assembly and 3-D detailing to aid in installation strategy, orcombine discrete elements into modular components with false joints to further streamline the installation process.

We have a well-earned reputation for efficient and comprehensive design and detailing of our work. Some of our most successful projects have evolved from a group consensus of the design, involving the project architect and engineer, masonry restoration contractor, and our design team. Unlike most construction documents that depict the general design intent, our final drawings attempt to capture all of the relevant information in a thorough and finite manner, from the bill of materials to the last joint.

Get a better look at our part detailing by scrolling over the plans above.

Tooling

Our model and mold-making (tooling) skills also combine a range of traditional and modern technologies - from clay or plaster sculpting and wood pattern work to computer-aided machining of models and molds. Since almost all of the thousands of molds we’ve created have been for custom work, we are particularly adept at developing tooling options that provide the best combination of economy and performance for the specific requirements of each project. Our skill at creating complex shapes allows us to accommodate your project needs in many different capacities, including providing our design and model/mold services to other pre-casters, contractors, and producers, sometimes in other parts of the country, when their production and/or transportation costs may yield savings, LEED credits, or both.

Molding and Fabrication

Architectural

Castings is especially skilled at shaping cement, gypsum, and polymer-based

materials, alone and in combination. The ability to reduce lead times when compared to traditional production methods, such as terra cotta, is a key benefit of many modern materials. Our in-house production primarily utilizes

Finishing

Our finishing department excels at successfully providing a final finish that will not only stand the test of time, but that also fits cohesively with the existing parts around it. It can be very challenging to blend the old with the new, especially because historic materials are often very weathered after years of exposure, and often differ from one elevation to another. After many years of experience customizing and sourcing appropriate colors, sizes and shapes of aggregates, and in media-blasting or etching techniques, we are extremely skilled at reproducing a variety of finishes and textures - for both integral finishes and applied finish coatings.

We look forward to hearing about your project.

Contact us and let's get into the nuts and bolts!