Architectural Castings was responsible for the design and production of an array of GFRC replacement pieces for the damaged and missing terra cotta elements at this historic 1921 theater in downtown Kansas City, MO. This was the sole historic building that was retained as part of the redevelopment of the new Power & Light District. Previous restoration on the facade had utilized a heavily filled polymer-based system to create replacement parts, but they had deteriorated to such an extent that we needed to replace many of those parts as well. Rather than constructing the molds so the parts could be cast as monolithic wholes, which is generally preferred for durability, many corners had been mitered and bonded together as a presumed cost saving measure. The polyester resin-based material that had been used to produce the previous replacement pieces was very prone to shrinkage, warping, and enlarging of joints, causing the mitered corners to break apart.

Extensive failures of the terra cotta cladding over the years had led to numerous patches and repairs, as well as large areas of banding below the iconic corner dome where the original terra cotta had been removed and infilled with brick. Our field work included several trips to the jobsite to obtain field dimensions, physical templates of profiles and various radiused surfaces beneath the dome, and to pull rubber molds off of several existing ornamental features. Since much of the original masonry was missing, most of the molds for the replacement parts were produced from new patterns that we created from information obtained at the jobsite, as well as historic drawings and photographs. In many areas our replacement work directly abutted areas of original terra cotta, so a precise match of the speckled multi-color glaze was particularly important. The new GFRC parts were produced with a single integral color that duplicated the underlying color of the terra cotta. We then over-coated with several colors of speckling that we developed in-house using Edison Coatings’ Aquathane materials, which were also used throughout the project to coat numerous patched areas of terra cotta.

We've always tried to design our projects with an awareness of the most cost-effective methodology regarding the aggregate costs of the production and installation phases, even where that may cause some cost shifting between the involved parties. A number of the replacement parts for this job involved individual pieces at widely spaced locations around the facade, so the potential for connection approaches that could reduce the installation labor were limited, as single parts typically fit into blind holes where the connections are via stainless rods threaded into the castings which are then set into epoxy filled field-drilled holes. Even where there were large groupings of new replacement parts around the base of the dome, the installation contractor choose to forgo our offer to design connection methods that could have reduced their field labor, as well as our plan to provide drill templates that we make off of the templates used to locate the threaded inserts within our castings. The stainless/epoxy pin approach is certainly simple, although somewhat labor intensive, but in this case the contractor felt they could better utilize their crew with this low-tech approach compared to a more complex system that might have required a wider range of worker skills.

Before and After Photos

Failing terra cotta around the base of the theater dome had long since been removed and in-filled with brick. High quality historic photos were found to help guide the design of the GFRC replacements.

The renovated theater facade.

Additional Photos

A filled polymer-based material used to produce previous replacement pieces had proven to be prone to shrinkage and warping, enlarging of joints, and the breaking apart of corners that had been mitered and bonded together.

Our crew spent a number of days on the job site obtaining field dimensions, profile templates, and a mold made from a remaining original part. And yes, that’s snow; it always snows when we do field work.

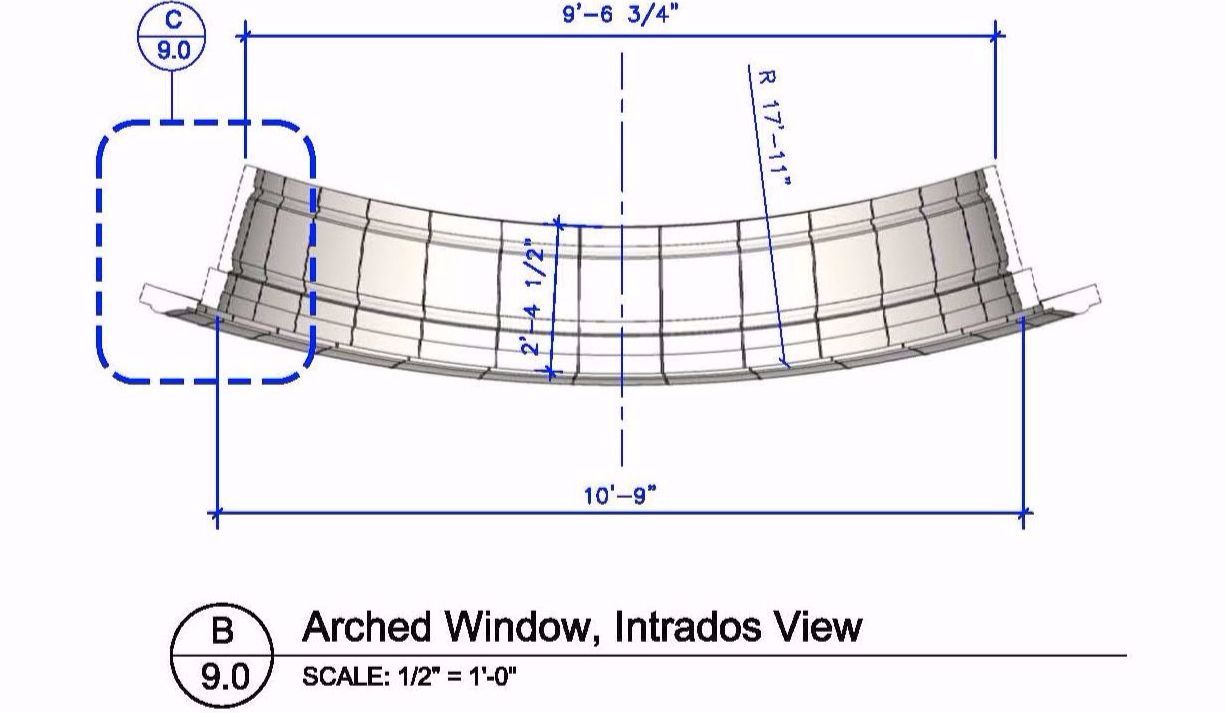

Even with conventional design/bid/build projects, we spend a good deal of time fleshing out the architectural intent with our shop drawings. Rendering complex part layouts and profiles three-dimensionally allows us to avoid time and labor intensive mock-ups later.

A trial assembly of new patterns that were created for the missing areas of radiused banding above the cornice.

Project Architect:

Helix Architecture + Design

Trudy Faulkner, AIA

Kansas City, MO

Installation Contractor:

Hoffman Cortes Restoration

Charles Scammell

Kansas City, MO