The Sovereign Hotel in downtown Portland, Oregon has served many purposes, including being home to radio station KFWV and the Oregon Historical Society. Designed by Portland architect Carl Linde and completed in 1923, it is recognizable by its iconic large-scale murals that depict important figures of Oregon's history. In 2016, we were engaged in the renovation of the building. The functional balconies were the major piece of this restoration project, although various areas of balustrading and rusticated Ashlar pieces were also replaced.

The balconies of The Sovereign Hotel all exhibited major cracks and spalling. Their iron railings, original to the building, penetrated through the top of the terra cotta balcony as a way of attachment. This allowed moisture to penetrate the structure, and contributed to rust jacking and degradation of the metal. In all, 37 balcony assemblies needed to be replaced, in addition to balustrades for the 2nd floor mock-balconies.

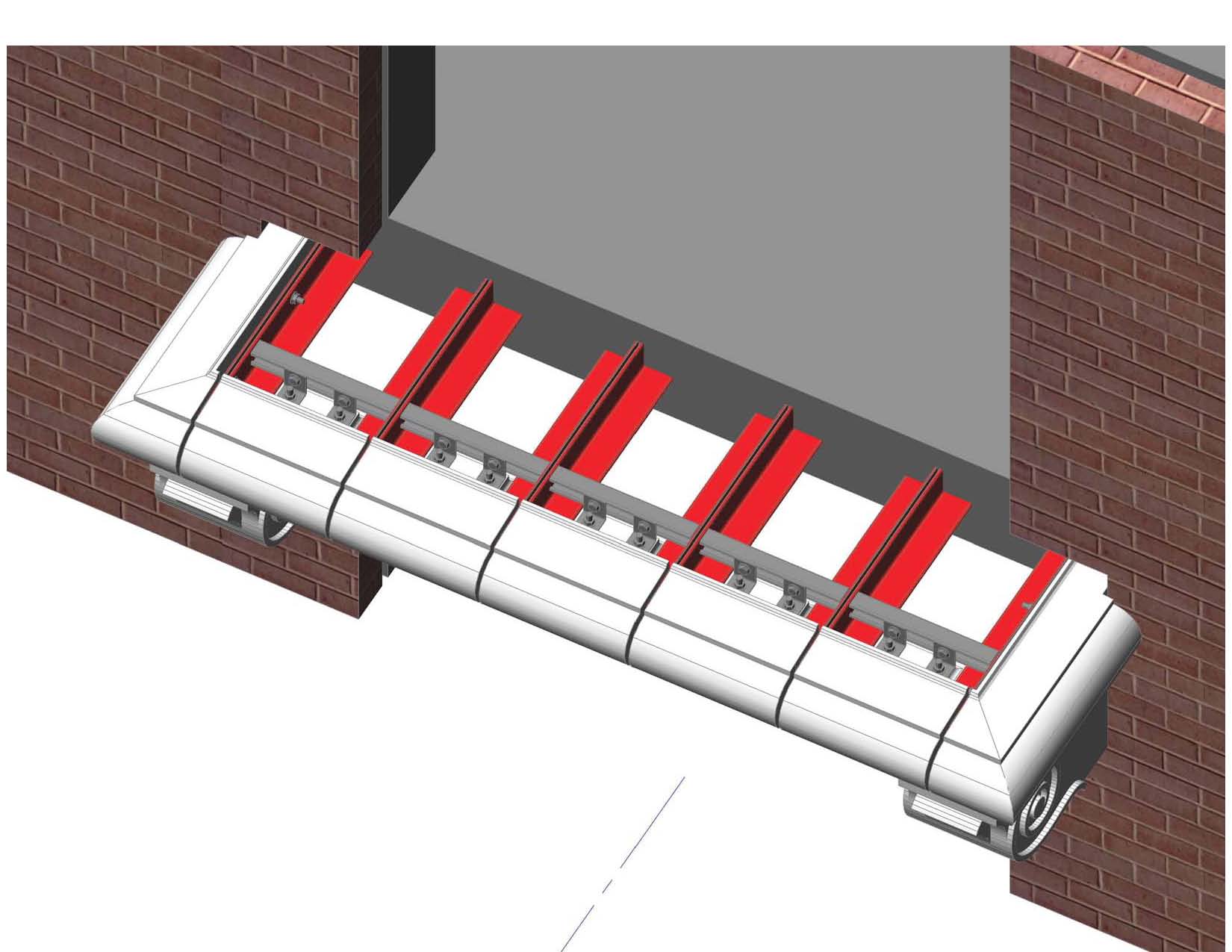

Our scope of work included field dimensioning of the three different balcony styles, the design and engineering of the replacement components, and supplying of GFRC parts with an applied paint finish to match the existing terra cotta glaze. In this case, our drawings specified and defined the complete mounting system, but the sourcing of the attachment components was done by the masonry contractor as the majority of these were off the shelf materials.

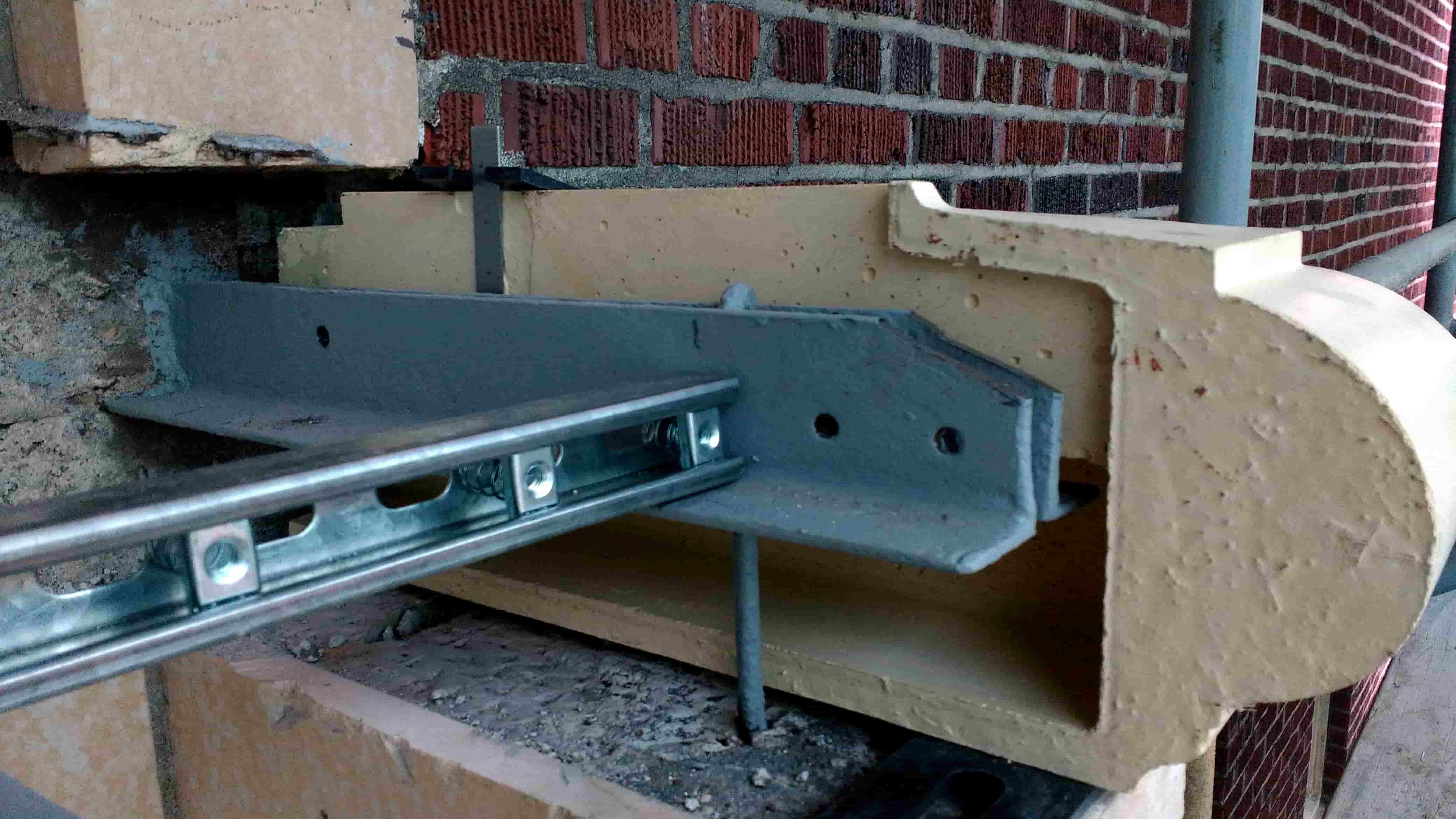

Originally the balconies supported much of the weight of the wrought iron railings. Our design incorporated sloped feet for the posts that rested upon a thickened area of GFRC, sandwiched between hot dipped steel supports, thus eliminating the original penetrations of the railing posts.

Before and After Photos

Additional Photos

The weight of the railing was further alleviated using a

re-installation approach, utilizing long stainless-steel rods that were set into epoxy in the masonry walls. This attachment system now carries a large portion of the several hundred pounds of the wrought and cast-iron assemblies.

This was another job where the first look at the rust and exfoliation in the structure made it appear total steel replacement was going to be required, but after closer assessment of the remaining wall thickness, the potential for its salvage and restoration became clear.

Mockup assemblies are often helpful, pre-installation, to ensure the fit of the parts and testing of the connection systems. For this project, one of the changes that resulted from the mockup was a shift to welding of the uni-strut support system. This was in lieu of the nut and bolt design that required site drilling of heavy steel members.